Solution: Cross-contamination is prevented by means of good cleaning and sanitization procedures, committed creation zones, and controlled airflow to stop item Get in touch with concerning different batches.

An answer is usually to cleanse the containers with significant-stress sterile air following it is formed to evacuate any free particulates. The creation location exactly where the sterilized drug products as well as the container are exposed to the environmental ailments is called the ‘crucial place’.

This automated approach permits the effective and aseptic manufacture of these containers, cutting down the chance of contamination and making certain the safety and high-quality of the final solution.

“In essence, you have to handle course of action parameters to cool the container prior to the drug item contacts The interior floor,” describes Goll.

With our assistance, you keep the tools up to date and generally develop competently. Frequently, uncomplicated changes or a completely new form are all it will take.

Sealing: After the container is filled, the open up stop is sealed to make a hermetically sealed offer.

BFS technology is classed as a sophisticated aseptic producing process that minimizes product exposure and removes possible resources of contamination, for instance element washing and operator interventions.

For BSL-1 products and solutions, this isn't as well tough, but as you rise in your biosafety levels You need to consider this into account and understand how you're going to manage it.” Eventually, most vaccines demand a chemical or warmth inactivation stage. Both are possible because a BFS equipment has an integrated CIP and SIP system in just it. Pauzer pointed out, “Some solutions need a specific chemical. So rather then a cleaning phase, you need a genuine inactivation stage just before opening the equipment up and just before likely more info to drain along with your product.”

Name your assortment: Title has to be under people Choose a collection: Not able to load your selection due to an error

a worldwide chief in enhancement options and Highly developed drug shipping systems. During this purpose he is liable for Catalent’s industrial operations functions for the corporate’s Drug Delivery Options services from the U.S. Earlier, Monthly bill served since the Director of Commercial Operations and System at Catalent’s facility in Woodstock, Illinois, and was answerable for the company’s ADVASEPT® Innovative aseptic technology, and for your implementation of a complete suite of advanced aseptic processing solutions for biologics and sophisticated pharmaceutical liquid merchandise.

We happen to be providing significant-good quality products and solutions to patients for practically 30 a long time. We're committed to constantly exploring approaches to enhance our facilities, our folks, and our processes, with the last word objective of serving to more sufferers.

It requires forming the container, filling it While using the merchandise, and sealing it in one constant process. This system is often employed for solitary-use vials and ampoules, making certain product or service sterility and integrity.

“For oral shipping to young youngsters, such as, the GSK rotavirus vaccine container was developed with a longer, slim tube for that opening so that it would in shape very well In the youngster’s cheek. Containers check here for injectable vaccines might be designed to fit to some individual needle hub.”

The most recent Variation, ADVASEPT LOCK, incorporatesa Luer Lock style connection, combining the safety benefits of aseptic filling which has a effortless closure that eliminates the need of needles and possible sharps accidents affiliated with glass ampoules.

Amanda Bynes Then & Now!

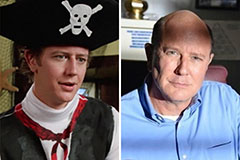

Amanda Bynes Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!